cnc lathe machine programming examples There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.

36 in. Workpro Lateral File Cabinets at Office Depot & OfficeMax. Shop today online, in store or buy online and pick up in stores.

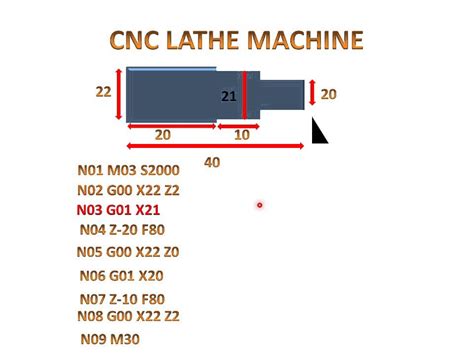

0 · sample cnc program for turning

1 · cnc turning program examples pdf

2 · cnc programming examples with drawing

3 · cnc programming examples pdf

4 · cnc lathe sample program

5 · cnc lathe programming pdf

6 · cnc lathe programming manual

7 · cnc lathe programming for beginners

CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. In this blog post, we will delve into the world of CNC lathe machines, explaining their working principles, applications, benefits, and .

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus .This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation .A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc .

electrical box spark guard

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .In this comprehensive guide, we will take you through the fundamentals of CNC lathe machine programming, covering everything from understanding the basics to mastering advanced .There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.

I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation M19 can be found here also.A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.In this comprehensive guide, we will take you through the fundamentals of CNC lathe machine programming, covering everything from understanding the basics to mastering advanced techniques.There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .

This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation M19 can be found here also.

A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

In this comprehensive guide, we will take you through the fundamentals of CNC lathe machine programming, covering everything from understanding the basics to mastering advanced techniques.There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

electrical box that mounts to drywall

sample cnc program for turning

electrical box suspended ceiling

cnc turning program examples pdf

cnc programming examples with drawing

JCS Woodworking & Manufacturing is a precision CNC machining shop providing component parts in Woods, Metals and Plastics. Services we provide: CNC Routing - 2D & 3D in wood and plastic CNC Machining - Milling in metal and plastic CNC Machining - Turning in metal and plastic laser cutting and engraving - 2D & 3D 3D laser scanning

cnc lathe machine programming examples|cnc lathe sample program